Welcome to

Azur Electronics

Azur Electronics

REPAIR HP 8018A

SERIAL DATA GENERATOR

SERIAL DATA GENERATOR

Home

Projects

Test Equipment

- Accessories

- Adaptors

- Amplifiers

- Attenuators

- Cables

- Frequency Counters

- Logic Analysers

- Multi-Meters

- Network Analysers

- Oscilloscopes

- Power Meters

- Power Supplies

- Prototyping Equipment

- Signal Generators

- Spectrum Analysers

- Tools

Operating Information

- Operating HP 141T

- Operating HP 1630D

- Operating HP 8175A

- Operating HP 8407A

- Operating HP 8410C

- Operating HP 8552B IF Section

- Operating HP 8553B RF Section

- Operating HP 8554B RF Section

- Operating HP 8555A RF Section

- Operating HP 8556A LF Section

- Operating HP 8594E Spectrum Analyser

- Operating HP 8901B

- Operating LeCroy 9310

Technical

- Allen Key Sizes

- High Voltage Measurement

- HP Cases

- HP Information

- HP-IB Interface Bus

- Measurement Units

- Motorola ECL

- RF Connectors

- RF Power - Voltage Conversion

For Sale

Wanted

Links

About Me

Contact Me

Site Map

January 2017

The HP 8018A Serial Data Generator is a complex item of test equipment with lots of inter-connecting coaxial & ribbon cables in between the pcb's and to the front panel. I have two of these Generators to repair and test.

The HP 8018A Serial Data Generator is a complex item of test equipment with lots of inter-connecting coaxial & ribbon cables in between the pcb's and to the front panel. I have two of these Generators to repair and test.

Power Supply testing

Initial testing identified a fault with the Power Supply. The -5.2V rail was not regulating correctly and oscillating badly. This fault was common to both units. The +25V rail and +5V rail were both ok.

Decided to strip down both units to assembly level.

Decided to strip down both units to assembly level.

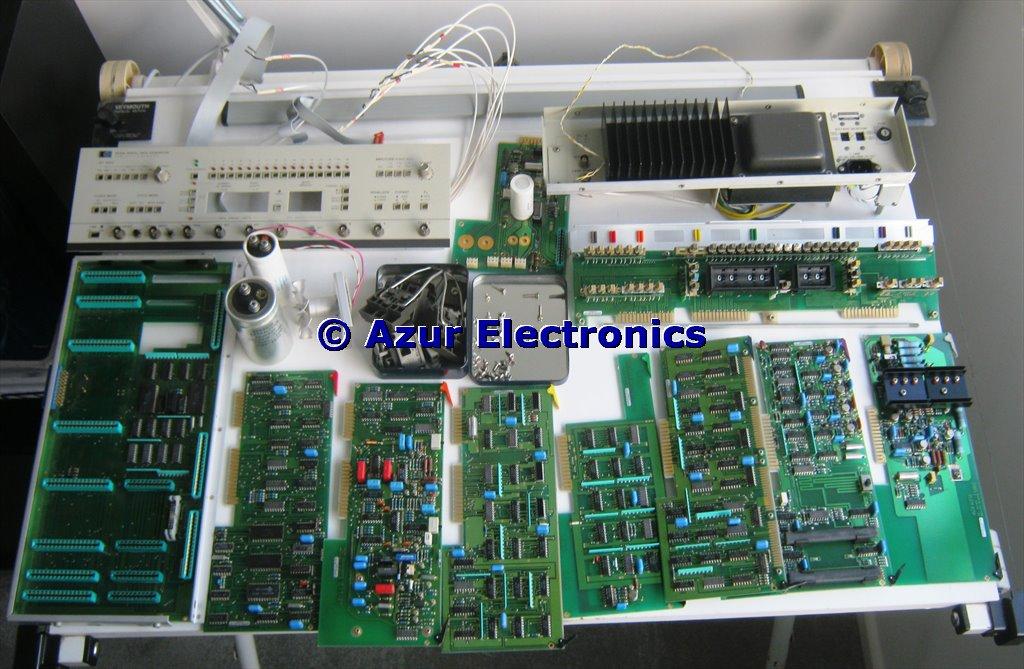

Kit of Parts!

The 8018A stripped down for cleaning and inspecting. Easy to dismantle although notes and photos required to identify where everything fits.

I'm surprised how many different designs of linear power supplies HP came up with over the years. Some have been good, efficient and easy to manufacture. This one IMHO is not one of these! The circuit design is very complicated for the -5.2V rail with two operational amplifiers (LM307 obsolete) and three transistors, plus a poor pcb track layout, all of which I suspect is unstable and with the addition of a difficult mechanically assembly.

March 2017

After fault finding unsuccessfully for some time, I gave up and redesigned the circuit with a LM337 Voltage Regulator and a higher current bypass transistor. This is a definitely a first for me with HP designs! Maybe it is something to do with the 8018A being manufactured in West Germany back in the 1970's? One of my own engineering principles is for the design engineer to actually build the first ten production units, that way any manufacturing problems soon get resolved!

I'm surprised how many different designs of linear power supplies HP came up with over the years. Some have been good, efficient and easy to manufacture. This one IMHO is not one of these! The circuit design is very complicated for the -5.2V rail with two operational amplifiers (LM307 obsolete) and three transistors, plus a poor pcb track layout, all of which I suspect is unstable and with the addition of a difficult mechanically assembly.

March 2017

After fault finding unsuccessfully for some time, I gave up and redesigned the circuit with a LM337 Voltage Regulator and a higher current bypass transistor. This is a definitely a first for me with HP designs! Maybe it is something to do with the 8018A being manufactured in West Germany back in the 1970's? One of my own engineering principles is for the design engineer to actually build the first ten production units, that way any manufacturing problems soon get resolved!

Modified Power Supply Assembly

Now I have a functioning power supply which when fully loaded requires about 120W so the heatsink gets hot! I made sure that all the components fixed to the Rear Panel heatsink had fresh heatsink compound.

With all PCB's plugged in the current loads are: +25V rail 300mA; +5V rail 2.3A; -5.2V 6.5A; so probably a lot of ECL circuitry.

With the new complete Operating and Service manual from Artek I can start testing.

Adjustments on both units completed ok. Most of the Performance Tests on both units completed ok, didn't bother with PRBS tests as specific test equipment not available and PRBS will not be required anyway. Pleased that both units were fault free even after 40 years.

With all PCB's plugged in the current loads are: +25V rail 300mA; +5V rail 2.3A; -5.2V 6.5A; so probably a lot of ECL circuitry.

With the new complete Operating and Service manual from Artek I can start testing.

Adjustments on both units completed ok. Most of the Performance Tests on both units completed ok, didn't bother with PRBS tests as specific test equipment not available and PRBS will not be required anyway. Pleased that both units were fault free even after 40 years.

Completed Repair